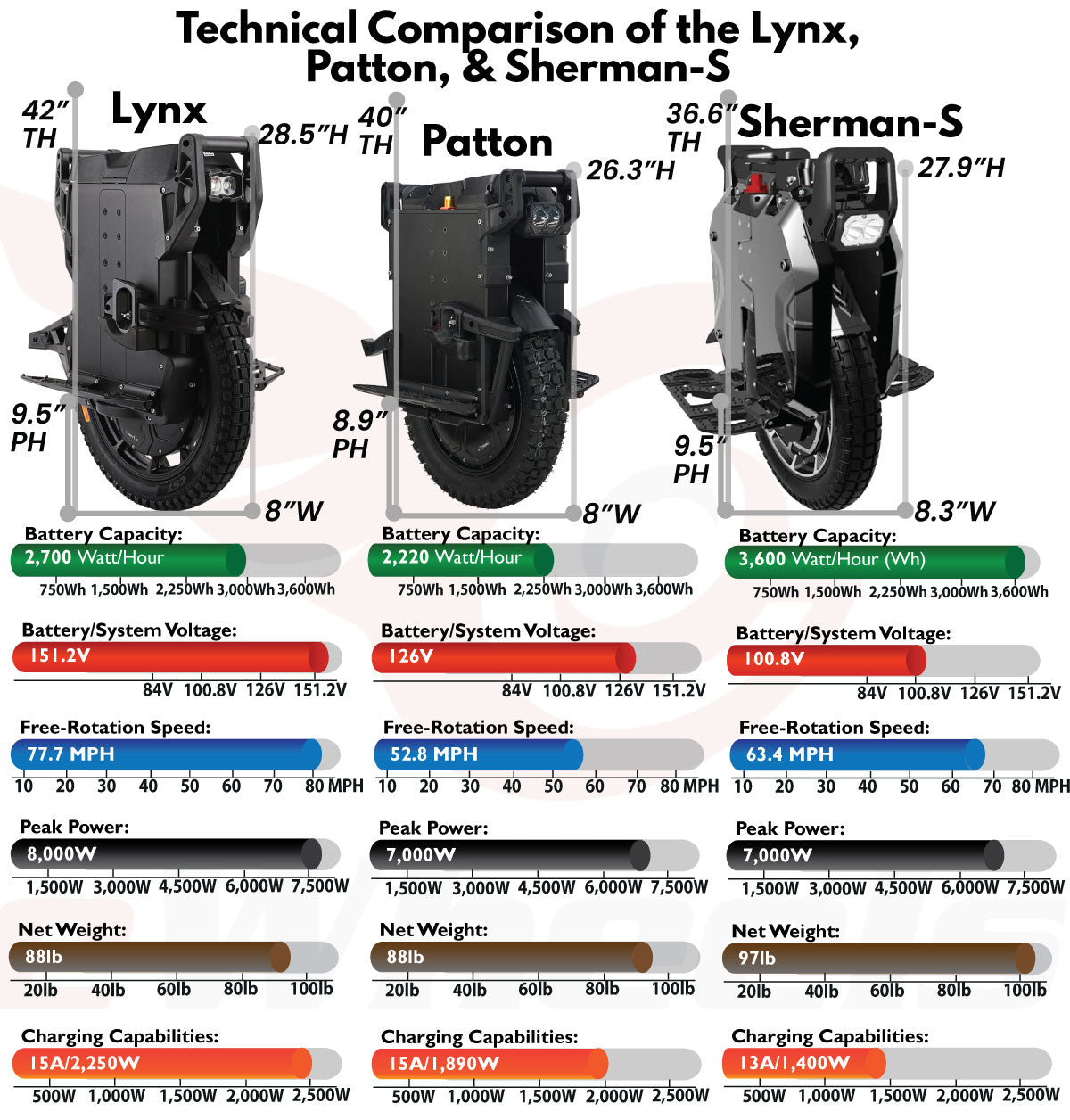

Leaperkim Lynx, 2,700Wh Battery/3,200W Motor (8KW Peak)

- Back in Stock

-

Bonus: Powerpads, Pedal Lowering Bracket, & Seat, $400 in value

- Motor: 3,200W (8KW peak) high-torque motor. With the first ‘no-load’ spin rate of 125KPH

- Weight: through the use of magnesium alloy, Veteran has been able to keep the weight at ~40kg/88lb, while increasing the size of the motor/tire & an additional 500Wh of battery capacity!

- Battery Pack: high-power Samsung 50S 2,700Wh/151V battery pack, with SmartBMS, capable of rapid-charging to 15A/2,250W

- Controller: first Wheel to use 36x 200V/140A MOFSETS, with a maximum current peak output of 840A

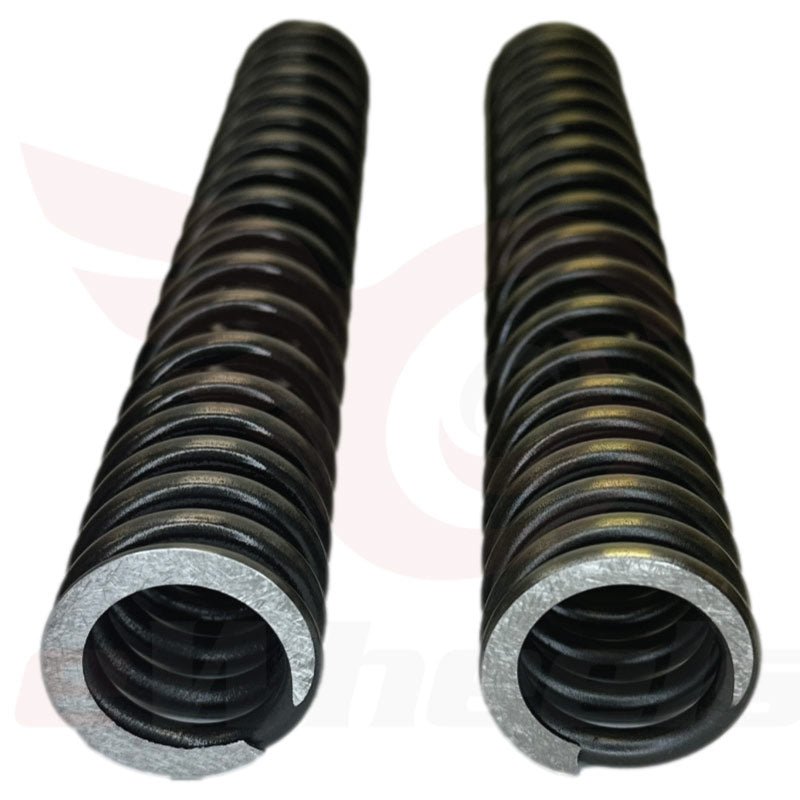

- Suspension: 90mm of functional travel, using the highly customizable Fastace suspension modules. Available in three different spring weights, 62/66/70lb

-

Tire: TNT tubeless street tire or tubeless knobby tire.

Lynx Overview

The Lynx is the first Electric Unicycle to break the >151.2V barrier. In principle, the advantages of using a higher voltage system are: higher potential efficiency, reduction in the gauge of wiring required, & greater rotational speed. To support this higher voltage, the Lynx required a new/uprated MOSFET (the electronic switches that power the motor), using 32x of the HYG100220NS1P chips, rated for up to 200V @ 140A peak current/each. The controller is designed for a theoretical maximum peak power rating of 840A @ 150V, for an astonishing 126KW! Clearly there are other bottlecks in the system, but at the MOSFET level, never before has this level of power been achieved.

Another first, for Veteran, is the introduction of their SmartBMS into the battery packs. This feature allows greater insights into the health of individual battery cells, such as cell voltage variance/drift, with half-a-dozen independent temperature probes across several cells & components on the BMS. A SmartBMS also provides allows for configuration of battery parameters for fine-tuning & optimization, with the need to make physical hardware changes & modifications. Similar to the Patton, the Lynx is packaged with all the amenities of a modern Wheel: integrated trolley handle—that extends to 42″— built-in kickstand, adjustable 2500lm/20W headlight, large 10″ footplates, & front/rear handles for lifting the Wheel.

Frequently Asked Questions

How does the Lynx fit into the current Veteran product line-up?

With the release of the Lynx is the Patton still relevant?

How does one choose the appropriate shock resistance for a given weight & use case?

What type of battery cells are used in the battery packs?

What stock charger is shipped with the Lynx & what other charger options will be available?

How is it possible to achieve the rated 15A of input charge current?

With the 151V Pack/System, is it possible to increase the speed even more?

Which other tires are compatible for the Lynx?

The Specs have a maximum weight limit of 120kg/264lb, what are the areas that are susceptible to fatigue with increased load?

Has Leaperkim made improvements to the bearings/seals on the Lynx?

The Lynx Has a Light Tread

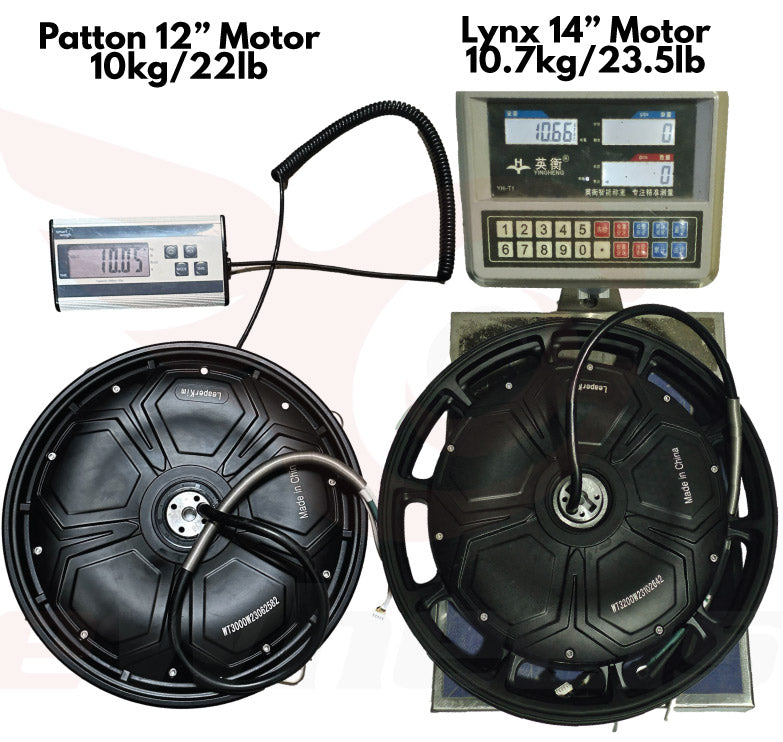

On the Lynx, the Veteran engineering team took great pains to reduce the net weight by using lighter (but stronger) magnesium alloy materials on the critical areas of the battery cases, controller tray/base & motor. The effect of this work has been to yield 14″ motor (20″ tire) vs 12″ motor (18″ tire), with more power, & 21% more battery capacity at the same weight as the Patton at 88lb, this is the first time any manufacturer has been able to offer a significant specification upgrade, while simultaneously keeping the weight the same as an earlier model.

To illustrate where these weight saving measures have been achieved, the comparison photos below demonstrated the main areas of focus:

– Motor/Rim: despite the 2″ larger diameter & containing more copper in the stator, the Lynx 14″ motor assembly is just 0.7kg more than the 12″ Patton motor. If the same aluminum alloy was used on the Lynx rim, one would expect to see a motor weight of about ~13kg/28.6lb.

– Metal Battery Cases: here is where the maximum effect of the magnesium substitution is realized, without sacrificing the strength; on the Patton each battery case is a hefty 2.7kg/5.95lb, while on the Lynx the same component is just 1.82kg/4lb. As the Wheel contains a set of these, the net savings is nearly 4lb for a larger battery case!

– Controller Base/Tray: finally there’s the controller base, which also serves as the heatsink. The Patton has a hefty block of cast aluminum, weighing in at 1.25kg/2.75lb. The Lynx’s controller tray (a more complex shape/geometry) at almost half the weight at 0.7kg/1.54lb.

All combined, it came as a delightful surprise to see these various weight shedding measures yield a next generation Wheel, at the same weight as the Patton.

Lynx ‘Progressive’ Shock/Spring

One of the new innovations of the Lynx is the use of ‘progressive’

springs, where there is a higher density of turns on the lower section

of the coil, this results in more resistive force applied when the

shock is at a state of high compression, such as on jumps, steps, or

trail-riding. From early Customer feedback, the net effect of the new

shock is a reduction of ‘bottoming-out’ for heavier riders, even those

on the lighter 62/66lb shock. If you're planning to do bigger drops and jumps, you'll want to lean towards a heavier spring option. If you're planning to do commuting on streets with the occasional curb drop - you can lean towards a lighter spring option.

Recommended Suspension Weights

In general:

- 62lb, for riders up to around 190lb

- 66lb, between 190-220lb

- 70lb, >220lb

NEW: Upgraded Samsung High-Power 50S Battery Pack

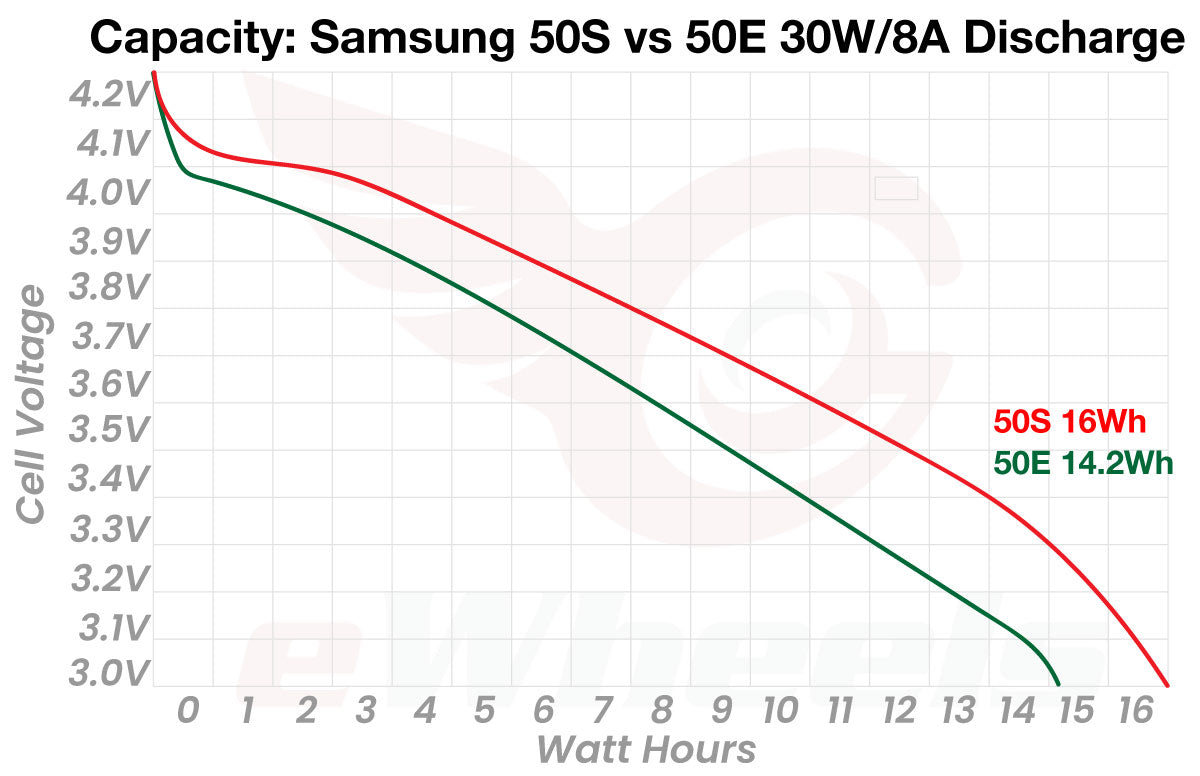

The most valuable component of any Wheel is its battery pack, the beating pulse of the machine. Over the years it has been found, from painful experience, that pairing a high-powered machine with a battery cell that is not designed for high peak-power applications can result in latent/delayed catastrophic thermal runaway events. To try to minimize this risk, we at eWheels, have insisted the use of high-powered battery cells, particularly on smaller 4 parallel packs, such as the MTen4, A2, T4, S18, Hero, S22, & Master—as the number of parallels increase, the load on each cells decreases accordingly. Until recently, there was the trade-off between power & capacity; now, with the advent of the new Samsung 50S cell, one can have both!

- Energy Density: 50S has a 20% increase in energy density over the 40T, providing a corresponding increase in range without any weight/bulk penalty.

- Higher Operating Temperatures: the specifications of the 50S has a vast operating range, from -20 to 80°C/-4 to 176°F vs -20-60°C/-4-140°F with the commonly used 50E/GB cell & as high as 100°C/212°F in Samsung’s test data! This massive margin not only allows the 50S to output up to 3x more power than the 50E, but perhaps more importantly, will greatly improve battery pack safety, there is no conceivable scenario in which these limits will ever be reached, or exceeded.

- Power Output: the maximum sustained power output on the 50s is 45A vs 15A on the 50E. At pack level, this represents a total potential sustained output of 15,120W, on the Lynx. From a Rider’s perspective, the main benefit of having this power on-tap is once the pack(s) have been partially depleted, reducing the risk of cut-outs when power is required.

- Rapid-charging: another benefit of the 50s over the 50E is charging rates, 2.25x higher, 6A vs 2.5A. It should be noted that although the cell supports the higher charging current, there may be other factors that limit maximum charge rate, such as the charge-port, wiring & BMS components. On the Lynx, the maximum rate of charge should not exceed 16A.

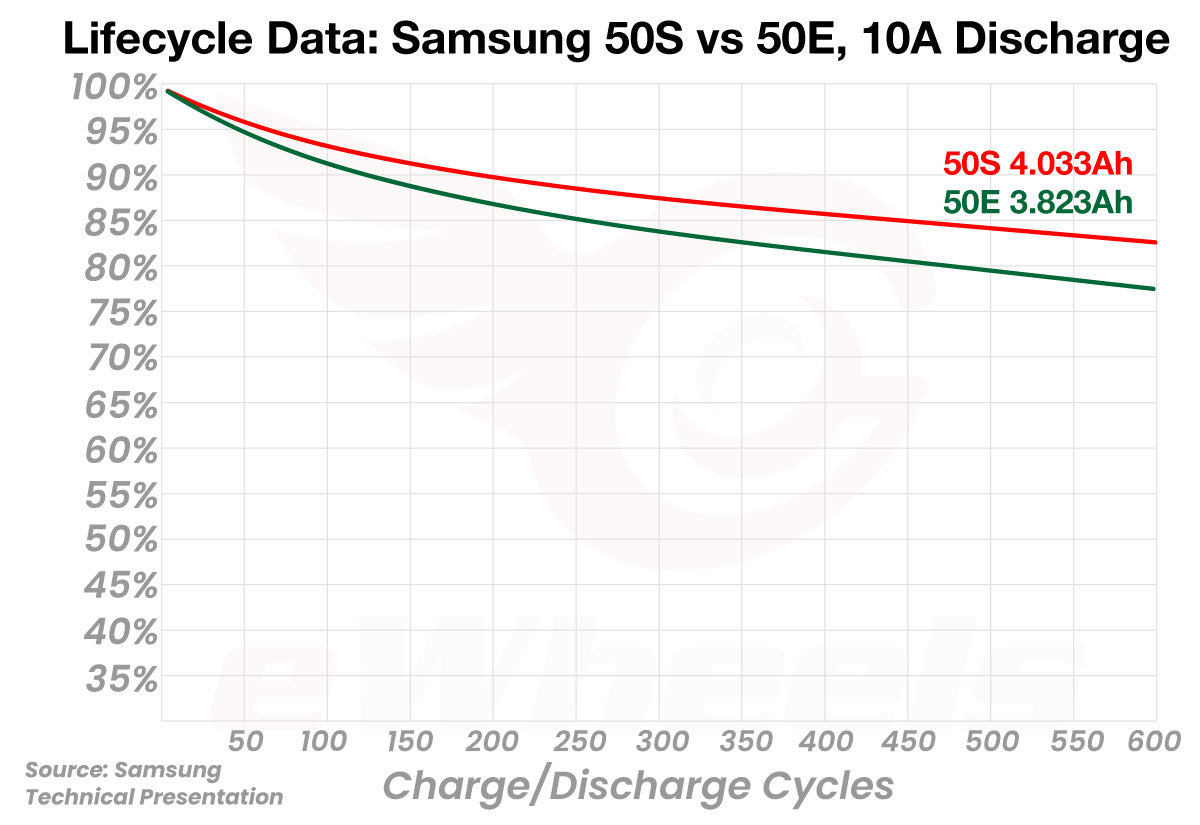

- Superior Cycle-life: perhaps the most common misconception of high-power cells is that of reduced cycle-life, but this is fundamentally a misunderstanding of the published datasheet for battery cells. In these publications, Samsung’s data is based on exceedingly high sustained loads of 25A/45A. Other Samsung materials demonstrates that in 10A continuous load scenario, the 50S commands a slight lead over the the 50E for longevity, with >82% capacity retention over 600 cycles.

It should also be noted that these synthetic tests in no way represent the power demand pattern that is experienced when using your machine, where the average load, on flat terrain, will be closer to 2-3A/cell vs the 10A in the test data—there may be periods where this demand is considerably more than the 10A, which is where the high-power cells really come into their element. In addition, the [50S] 600 cycles were charged at the maximum 6A vs a typical 1.5A (per parallel) with the stock charger, which also has an impact on the pack’s longevity.

In summary, the 50S battery cell is objectively superior in every measurable metric, with only a marginal increase in upfront cost. It is expected that machines fitted with these packs will retain their value better than other battery cells.

Lynx Accessories

The Lynx & Sherman-L share a number of interchangeable accessories, such as the CNC pedals, Cyclops headlight, and more. The seat kit, power pads, and pedal lowering brackets are available as optional accessories.

Lynx Photo Gallery